Cutting Tools

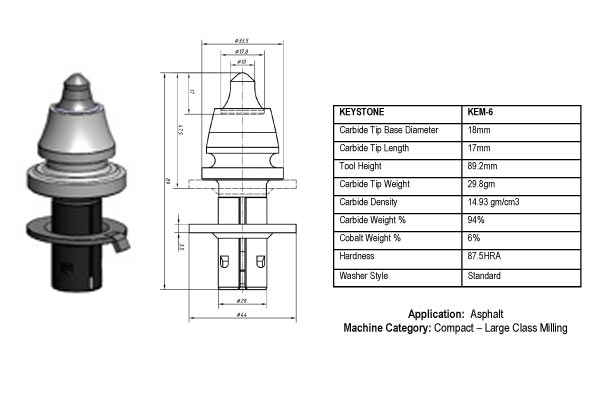

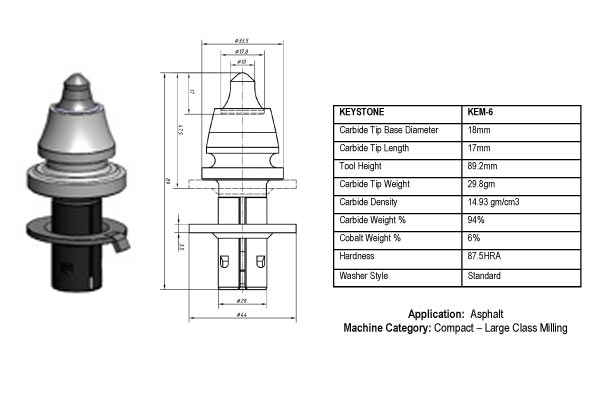

KEM-6 Carbide Tool

Tool Designed for Medium to High Horsepower Milling Machines

- Universal cutting tool that can be used on all OEM drum systems

- Extended retainer for even block/holder wear

- KEM washer

- Puller groove

- Extended sleeve

- 50 tools per box/ 2,400 pallet

KEM-6NRW Carbide Tool

Tool Designed for Medium to High Horsepower Milling Machines

- Patented non-rotating washer used to prevent block/holder face wear

- Universal cutting tool that can be used on all OEM drum systems

- Extended retainer for even block/holder wear

- Puller groove

- 50 tools per box/ 2,400 pallet

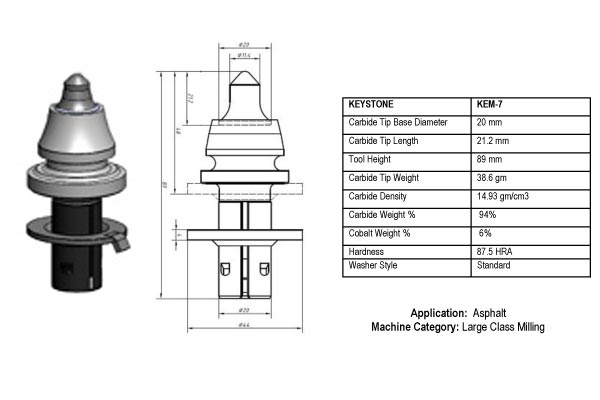

KEM-7 Carbide Tool

Tool Designed for Medium to High Horsepower Milling Machines

- Universal cutting tool that can be used on all OEM drum systems

- Extended retainer for even block/holder wear

- KEM washer

- Puller groove

- Extended sleeve

- 50 tools per box/ 2,400 pallet

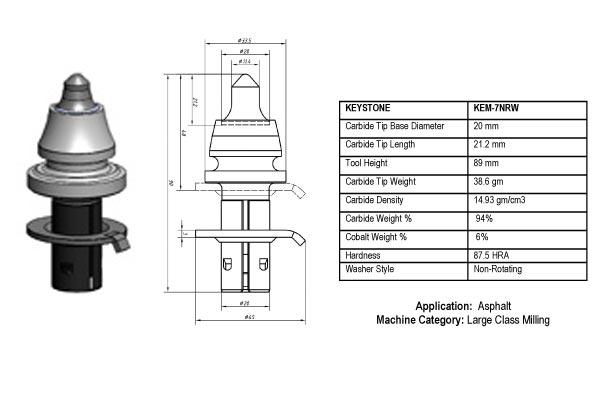

KEM-7NRW Carbide Tool

Tool Designed for Medium to High Horsepower Milling Machines

- Patented non-rotating washer used to prevent block/holder face wear

- Universal cutting tool that can be used on all OEM drum systems

- Extended retainer for even block/holder wear

- Puller groove

- Extended sleeve

- 50 tools per box/ 2,400 pallet

Slashbuster Tool

Carbide Tipped Slashbuster Tool

- Reduce labor cost

- Improve fuel efficiency

- Increase production

- Improve working conditions

SS Quick-Change System

- Cost effective alternative to diamond grinding

- Leaves a flat and smooth surface pattern without ridges or grooves

- The flat tool design eliminates surface damage seen with conical milling tools

- Completely machined tool and block ensures a uniform surface pattern

- The compound taper locking system pulls the tool in and down for precise alignment

- Carbide and PCD diamond tool options available

D540 PCD Tool

Keystone Engineering's D-540 PCD tool can easily be adapted to any quick-change grinding system. Interchangeable insert allows operators to easily change from carbide tools to diamond tools.

- Improve productivity by extending tool life by 40X

- Reduce fuel consumption by increasing cutting efficiency

- Reduce overall maintenance cost of the machine by significantly reducing vibration

- Carbide bolster extends the life of the diamond

- Creates a smoother and more uniform surface pattern

- Improve employee work environment by requiring fewer tool changes and minimizing machine vibration

D540-875 PCD Tool

Keystone Engineering's D540-875 PCD tool can easily be adapted to any quick-change grinding system. Interchangeable insert allows operators to easily change from carbide tools to diamond tools

- Improve productivity by extending tool life by 40x

- Reduce fuel consumption by increasing cutting efficiency

- Reduce overall maintenance cost of the machine by significantly reducing vibration

- Carbide bolster extends the life of the diamond

- Creates a smoother and more uniform surface pattern

- Improve employee work environment by requiring fewer tool changes

RS Quick-Change System

- Interchangeable tools for different grinding applications

- Change the cutting width by simply adding or removing tools

- 100% surface coverage with Keystone's flat tool eliminates the need for multiple passes during pavement marking removal

- Increase production by 3 times when compared to diamond blades and flail teeth

- Minimize surface damage while grinding

- Precision machined block and tool ensures a uniform surface

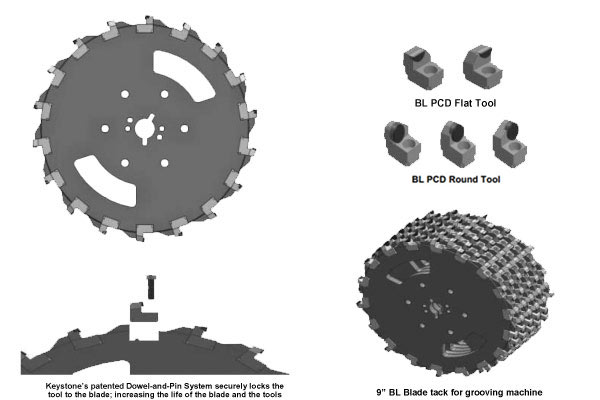

BL - PCD System Quick-Change Blade System

PCD Saw Blades Available for all Grooving and Grinding Machines

- Increase production by 4 times when compared to standard diamond saw blades and carbide flail tools

- Interchangeable PCD tools for different grinding applications

- 100% surface coverage with Keystone's BL flat tool eliminates the need for multiple passes while grooving and grinding

- Longest lasting and most versatile PCD tools on the market

- The most versatile blade system: Blades accept 3, 6, 9, or 18 tools

View Quick-Change BL - PCD System Product Card