Construction Attachments

Construction Attachments

Keycut - Milling

The KeyCut is a skid steer milling attachment for skid steers that is ideal for patching, utility cuts and trimming.

- 24" and 40" standard cutting width

- Custom drum width options available

- Custom designed drums available - Transverse rumble and dowel bar stitching

- 5" to 8" cutting depth

- Standard, fine and micro drum spacing options

- Tooled with Keystone's Easy Screw Quick-Change Block System

- Electro-hydraulic control of depth, side shift and tilt

- Independent depth skis for precise lap cuts

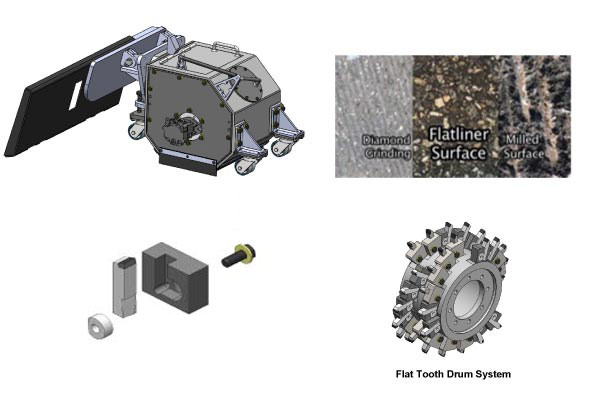

Flatliner - Precision Grinding

Ideal for -

- Maintenance Work/Bump Grinding

- Ride Quality/IRI Improvement

- Pavement Marking Removal

- Coatings Removal

Skid steer attachment designed to smooth pavement roughness by shaving high spots and other irregularities in a cost effective manner. The Flatliner uses Flat Tooth Technology, a machined and precise holder system to insure a smooth and uniform surface, setting a new industry standard.

- Precise Depth Control

- Variable Cutting Widths: 2" to 49"

- 100% Surface Coverage

- Precisely levels bumps and other irregularities, acts as a profilograph and bump grinder in one

- Utilizes Keystone Engineering's patented Flat Tooth Cutting Techonology

- 100% surface coverage, unlike diamond blades and other traditional carbide conical tools and flail cutters

- Minimal surface damage seen when comparing to traditional carbide tools and water blasting equipment

- No water required

Crack Routing Attachment

Crack Routing Attachment helps reduce material cost and increase production. Attachment utilizes Keystone Engineering's RS Quick-Change Drum System.

- Reduce material cost and increase production

- Route from .5" - 3.75" wide

- Accurate depth adjustment up to 2"

- Ejection system keep debris out of routed area

- Utilizes Keystone's RS Drum System

V-Head - Joint Repair

Skid Steer Attachment Designed for Longitudinal Joint Repair

- Remove and replace at deeper depths on the joint line or other targeted areas

- Requires less material

- Cuts a V-shape into the pavement that allows the new material to bond better to the existing pavement

- The tapered cut alleviates the shearing effect that is seen with the flat surface cuts

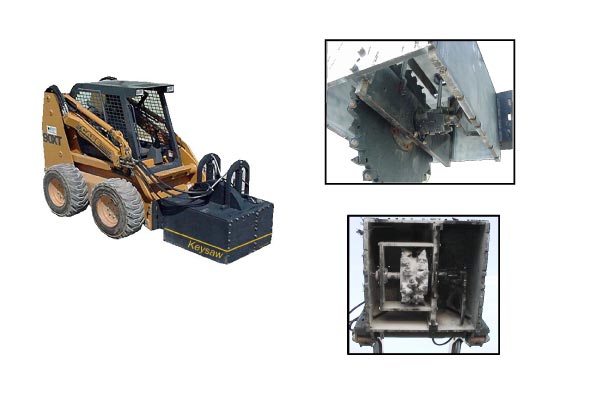

Keysaw - Concrete Saw

Skid Steer Saw/Cold Planer Attachment Designed for Cutting Concrete

- Asphalt and Concrete Sawing

- Partial Depth Concrete Repair

- Micro-Trenching

- Longitudinal Joint Repair

Micro-Grinding

- Reduce material cost and increase production

- Grind width between .5" to 2.5"

- Accurate depth control up to 1.5"

- Ejection system keeps debris out of grind area

- Utilizes Keystone Engineering's RS Quick-Change Drum System

Micro-Trenching

Cutting and Trenching Attachment

- Reduce material cost and increase production

- Trench between .5" to 2.5" width

- Accurate depth control up to 1.5"

- Ejection system keeps debris out of trenched area

- Ulitizes Keystone Engineering's RS Quick-Change Drum System

View RS Quick-Change Drum System Product Card

Pavement Marking Removal

- Optional self-contained vacuum system

- 100% surface coverage to eliminate the need for multiple passes during pavement marking removal

- Shaves the pavement's surface instead of impacting the surface like traditional carbide conical tools that are used in asphalt milling machines

- Minimized surface damage during pavement marking removal. Far less damage seen by the Flat Tooth System than by water blasting equipment and traditional asphalt grinding products

- Leaves a level and smooth surface unlike a milled surface or a diamond ground surface

View Flatliner Product Card

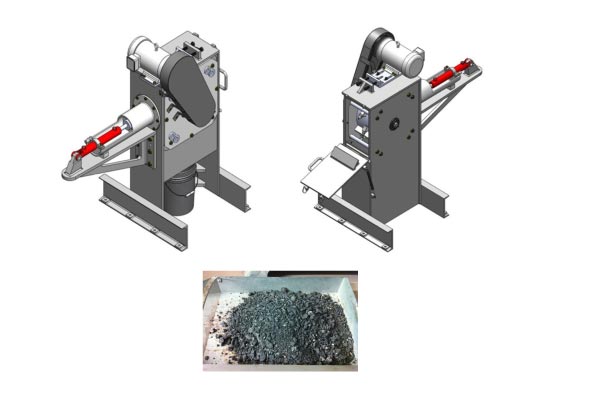

Material Processing

Lab Core Crusher

- Creates material that is representative of field milling

- The crusher's drum design replicates an actual milling machine's drum with similar wrap design, tooth spacing and drum RPM

- Saves time by crushing cores in seconds and eliminates the need for a jaw crusher

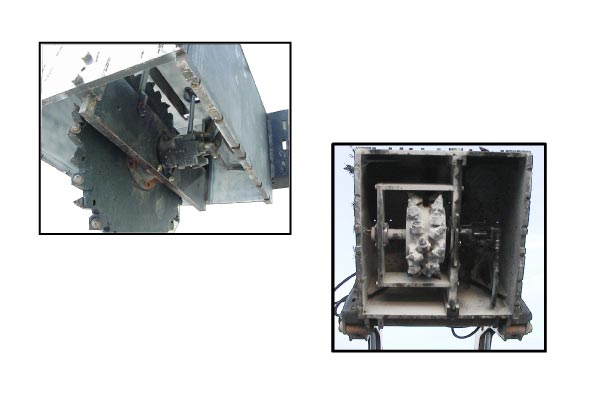

Underground Mining

Keysaw Mining - Underground Cutting and Grinding

- Sawing

- Grinding

- Micro Trenching

Aftermarket Drum Manufacturing for all Milling - Keystone will design and build replacement drums for all OEM skid steer attachments to meet any specification or specific need.

- Custom Width Attachment Drums

- Standard, Fine Milling, and Micro-Milling Attachment Drums

- Surface Grinding Attachment Drums

- Rumble Strip Grinding Attachment Drums

- Line Removal Attachment Drums

- Pavement Coatings Removal Attachment Drums

Attachment Drums

- Utilizes Keystone's proven attack and skew tool angles which allows the drum to cut more efficiently and drastically reduces tool consumption

- Machined and balanced shell minimizes vibration on the attachment

- Precise end ring placement with "The Edge" reduces wear on the blocks and leaves a clean edge cut

- Tooled with Keystone's patented Easy Screw Quick-Change System to eliminate the need for in-field welding

- Easy insert removal-unscrew holder with standard tools, no hydraulic presses or special tools required

- Taper on taper design provides a consistent holder locking depth, providing a uniform milled surface