- Home

- Construction

- Products

- Block and Tooling

Block & Tooling Systems

Wedge Lock Quick-Change System

- Interchangeable tool holders can achieve spacing of 5mm/7.5mm/15mm to meet any milling, fine milling or micro-milling specification

- The only drum system on the market that is designed to last the life of the machine, no costly rebuilds required

- Custom tailor the drum's spacing to increase or decrease the gradation of the RAP, on a job to job basis

- Change tools faster with easy access to the tool from the back of the holder

- Continuous wrap design provides superior strength

View Milling Wedge Lock Quick-Change System Product Card

Wedge Lock Quick-Change System for Mining

- Interchangeable blocks for different mining applications can convert a standard spaced drum into a rock drum without the costly expense of changing drums

- No tapered or threaded parts are welded to the drum providing a longer lasting block system. Industry standard taper systems wear and lose locking capability over time

- Continuous Wrap Design - Keystone's patented block to block welding technology insures superior strength in the most extreme mining environments

- Easily change from a standard mining tool to a radial mining bits

Easy Screw Quick-Change System

- Easy tool removal with access to the tool from the back of the block

- Easy insert removal, simply unscrew the insert with standard tools, no hydraulic presses or special tools required

- Taper on taper design provides a consistent locking depth, providing a consistently smooth surface pattern

View Easy Screw Quick-Change System Product Card

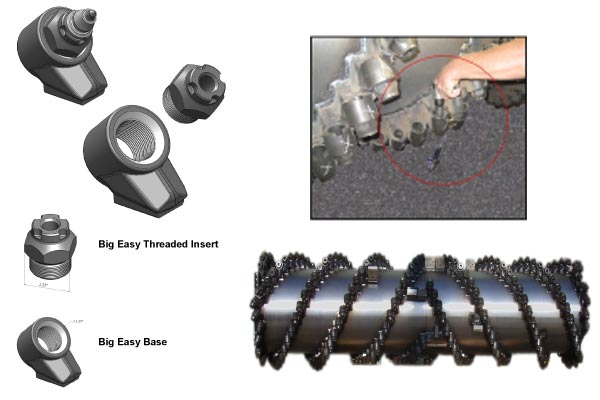

Big Easy Quick-Change System

- Easy tool removal with access to the tool from the back of the block

- Easy insert removal, simply unscrew insert with standard tools, no hydraulic presses or special tools required

- Continuous wrap design with block to block welding technology ensures superior strength

- Taper on taper design provides a consistent locking depth, providing a consistently smooth surface pattern

- 60% larger than Keystone's EZ Screw Quick-Change System

View Milling Big Easy Quick-Change System Product Card

Big Easy Quick-Change System for Mining

- Easy insert removal - unscrew holder with standard tools, no hydraulic presses or special tools required

- Interchangeable inserts provide unmatched versatility allowing for the use of multiple size shank bits for different mining applications

- Continuous Wrap Design - Keystone's patented block to block welding technology insures superior strength in the most extreme mining environments

- Keystone's patented threaded system provides more clamping force than industry standard taper systems creating a system that is stronger and lasts longer

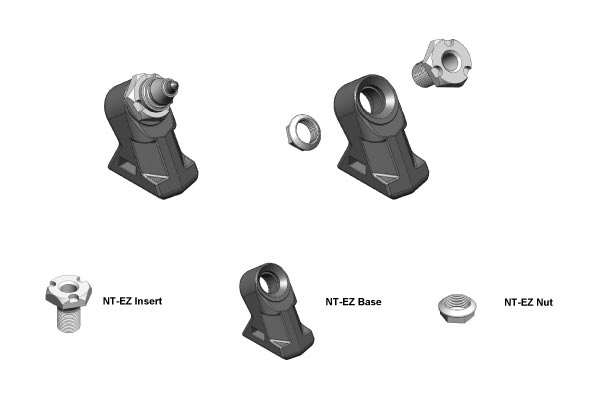

NT-EZ Quick-Change System

- Easy tool removal with access to the tool from the back of the block

- Easy insert removal

- No threaded parts are welded to the drum, providing a longer lasting drum

- Double taper lock system locks the insert into place, ensuring proper attack angles are held and maintained throughout multiple changes

View Milling NT Big Easy Quick-Change System Product Card

Trenching Vermeer-Earth Saw Segments

- Each tooth holder location is machined to achieve the best attack angle, extending tool life and increasing fuel economy with less abuse to your machine

- Made from 4140 high alloy wear resistant steel

- Equal circumferential spacing helps to reduce vibration

- Wear bars keep material off the bolt head making maintenance easier

- The side against the wheel is machined to a perfect flat, reducing vibration and providing longer life

- Mounting holes are threaded, eliminating the need for a nut on the opposite side

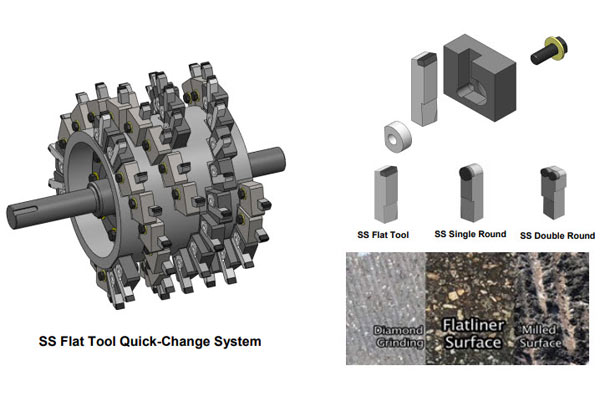

SS Quick-Change System

- Interchangeable tools for different grinding applications

- 100% surface coverage with Keystone's Flat Tooth bit eliminates the need for multiple passes

- Increase production by 3 times when compared to diamond blades and flail tools

- Minimize surface damage while grinding

- Precision machined block and tool ensures a uniform surface pattern

- Carbide and PCD diamond tool options available

- Replacement drums available for all grinding machines

View Surface Grinding Solutions Guide

RS Quick-Change System

- Interchangeable tools for different grinding applications

- Change the cutting width by simply adding or removing tools

- 100% surface coverage with Keystone's flat tool eliminates the need for multiple passes during pavement marking removal

- Increase production by 3 times when compared to diamond blades and flail teeth

- Minimize surface damage while grinding

- Precision machined block and tool ensures a uniform surface

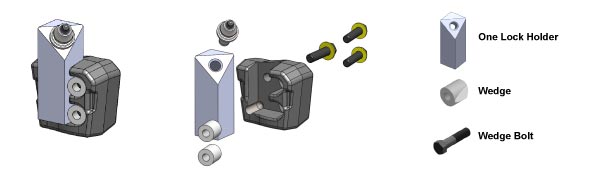

One Lock Quick-Change System

- The replaceable tool holders are not tapered, reducing the locking force and reducing the time required to change the holder

- Only one tool holder used throughout the drum, eliminating the need to stock multiple holders

- Designed to last the life of the machine, no costly rebuilds required

- Change bits faster with easy access to the tools from the back of the holder

View Milling One Lock Quick-Change System Product Card

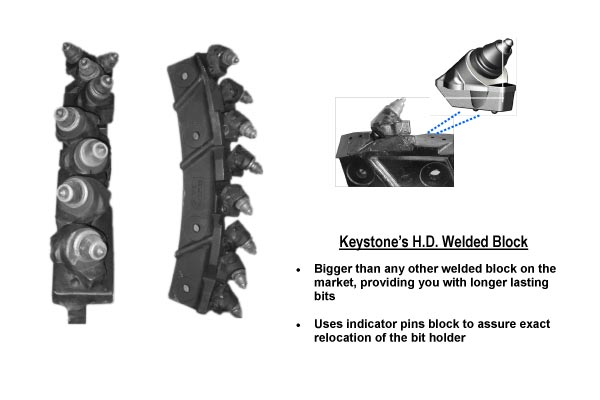

Heavy Duty Welded

- Largest construction welded block available

- Side wear tabs designed to deflect material

- Indicator pins assure exact relocation of the tool holder

- Large weld chamfers for extra strength

- Profile designed to increase cutting efficiency and improve material flow

Heavy Duty Welded - Trenching

- Largest construction welded block available

- Indicator pins assure exact relocation of the tool holder

- Large weld chamfers for extra strength

- Profile designed to increase cutting efficiency and improve material flow

- Custom designed to be compatible for all trenching tools

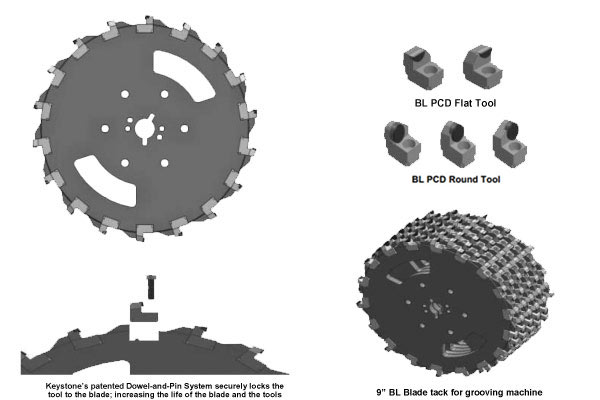

BL - PCD System Quick-Change Blade System

PCD Saw Blades Available for all Grooving and Grinding Machines

- Increase production by 4 times when compared to standard diamond saw blades and carbide flail tools

- Interchangeable PCD tools for different grinding applications

- 100% surface coverage with Keystone's BL flat tool eliminates the need for multiple passes while grooving and grinding

- Longest lasting and most versatile PCD tools on the market

- The most versatile blade system: Blades accept 3, 6, 9, or 18 tools

View Quick-Change BL - PCD System Product Card

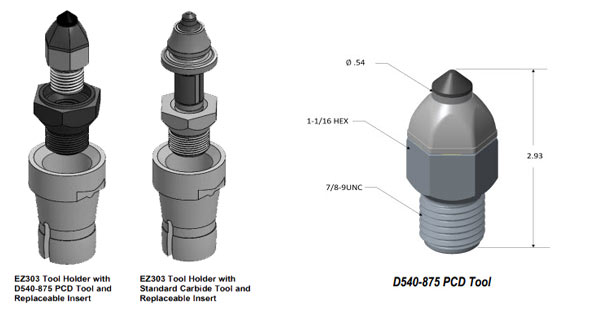

EZ540 PCD Tool Holder - Wirtgen Type 22

- Quickly change from PCD tools to carbide tools without having to change the drum or tool holder

- Replaceable steel insert significantly increases PCD tool life

- Keystone's patented threaded PCD tool is the only rigid mount three piece diamond system available: base block, tool holder, PCD tool

- Change PCD tools quickly with standard tools, no hydraulic presses or special tools required/li>

- Taper on taper locking design provides a consistent locking depth, producing a smooth and uniform surface pattern

- Right and left threaded PCD tools self tighten during the grinding process

View D540 PCD Tool Product Card

EZ540-875 PCD Tool Holder - Wirtgen Type 22

- Keystone's patented threaded diamond tool is the only rigid mount three piece diamond system: base block, tool holder, PCD tool

- Change PCD tools quickly with standard tools, no hydraulic presses or special tools required

- Taper on taper locking design provides a consistent locking depth, producing a smooth and uniform surface pattern

- Right and left threaded PCD tools constantly self tighten during the grinding process

View D540-875 PCD Tool Product Card

Kennametal KPF303 Toolholder

- Quickly change from PCD tools to carbide tools without having to change the drum or tool holder

- Replaceable steel insert significantly increases PCD tool life

- Keystone's patented threaded PCD tool is the only rigid mount three piece diamond system available: base block, tool holder, PCD tool

- Change PCD tools quickly with standard tools, no hydraulic presses or special tools required

- Taper on taper locking design provides a consistent locking depth, producing a smooth and uniform surface pattern